ABRASIVE AND YOU - CLUES TO HELP YOU CHOOSE

If you've ever puzzuled what to use here's a quick rundown to help you

Let's start with the main types

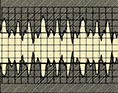

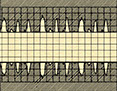

For the average user, the names of the two main abrasives are Aluminium Oxide and Silicon Carbide. Now, because many of you are largely interested in Flex-Hone use, we’ll explain a basic difference in the way abrasives work in things like grinding wheels in contrast to Flex-Hones. Let’s call grinding wheels “upwards cutting” tools and Flex-Hones “downwards smoothing” tools. By “upwards cutting” we mean each grain of abrasive is like a tiny, sharp lathe tool. It digs down under the surface and lifts metal off the workpiece. Flex-Hones work differently. They smooth over the tip of the surface and gently flatten the tiny sharp peaks left by machining or grinding. The diagrams to the right show the result.

Typical sharp roughness readout for grinding or machining finish.

Terms And General Things To Know

The way an abrasive will cut depends on a few characteristics – mainly:

-

- Hardness (technically measured by the “MOH” scale. The bigger the Moh number, the harder the abrasive).

- Shape and Size

- How easily and quickly each grain of abrasive breaks up into smaller particles after it hits the surface of the grinding job. This is called “friability”.

- Bonding of the Abrasive grains.

Roughness readout for “downwards” smoothed Flex-Hone finish which we call a “plateaud” finish.

COMMON TYPES OF ABRASIVE ARE:

SILICON CARBIDE

Is Just below diamond for hardness and more aggressive than Aluminium Oxide (AO). The particle shape is a bit sharper too, and the grains do not break up as easily as AO. In grinding wheel type operations it removes metal quicker and leaves a “rougher” finish than AO. In Flex-Hones silicon carbide is the usual general abrasive choice because its greater hardness knocks the tops off “sharpies” quicker and better for most materials. Because of the “downward smoothing” action of a Flex-Hone, the finished profile is smooth [exaclty the opposite to Silicon Carbide In a grinding wheel]. We call the finish left after Flex-Honing a “plateaued” finish-see the roughness readout pictures above the paragraph.

Grains of Silicon Carbide Look Like This

ALUMINIUM OXIDE

This Abrasive is very slightly softer than silicon carbide but more “friable” i.e. in use it breaks down into smaller particles quicker than silicon carbide. In grinding wheel operations it has a high metal removal rate but gives a smoother finish than silicon carbide because of it’s shape and “friability”. In FLEX-HONES aluminium oxide is generally used on plated cylinders. The reason is its more “block like” shape and its better breakdown [friability] means aluminium oxide is less likely to cut through the plating and lift pieces off the cylinder wall.

Grains Of Aluminium Oxide Look Like This

FINALLY THE SUPER ABRASIVES

Bronon nitrade(almost as hard as diamond) and Diamond are known as the “super Abrasives”.They’re expensive and only used on very hard materials